Process

SHEAR LINE PROCESS

Process

SHEAR LINE PROCESS

Shear line (including rotary shear) is a facility to correct flatness while continuously uncoiling the input coils, shear and cut according to the width and length requested by the customer, and then remove them after tidying the front and rear, left and right, and up and down evenly.

-

01 Incoming the coil

01 Incoming the coilConfirm that the product name, thickness, width, weight, and material number of the coil are consistent with the production instructions.

※ Appearance inspection upon arrival -

02 Unpacking

02 UnpackingRemove steel bands and wrapping paper outside the coil

※ Inspection before input -

03 COIL CAR

03 COIL CAREquipment that transfers and charges the COIL carried on the COIL SKID to the UNCOILER

-

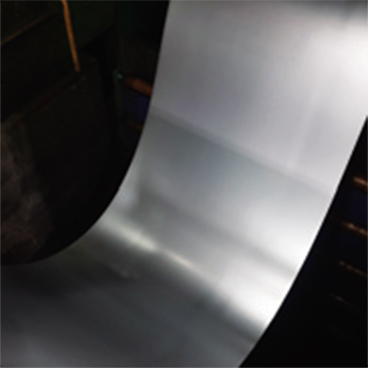

04 UNCOILER

04 UNCOILEREquipment that makes processing possible by loosening the coil

※ Thickness, width, and surface inspection -

05ROUGH LEVELLER

05ROUGH LEVELLEREliminates residual stress existing inside the material

-

06 LOOP

06 LOOPEquipment that enables speed synchronization with SHEAR and smooth centering work

-

07 SIDE TRIMMER

07 SIDE TRIMMERShear the width of the material and produce it in the size desired by the customer.

-

08FINISH LEVELLER

08FINISH LEVELLEREquipment that removes stress to favor the coil for shear

※ Flatness correction -

09VINYL SHEET COATER

09VINYL SHEET COATERPutting a protective film on the sheet

Used for (AL) operation -

10 SHEAR

10 SHEARSet the length of the product according to the demand of the customer and shear

※ Thickness, width, diagonal inspection -

11 CONVEYOR

11 CONVEYOREquipment that transfers the sheared sheet from the SHEAR to the piler

-

12 PILER

12 PILEREquipment that piles sheared sheet as much as the input quantity

-

13 Packing

13 PackingBinding the processed product with steel bands for easy movement according to the demand of the customer

-

14 Product storage

14 Product storageStore in SKELP Zone for each company to enable rapid shipment using CRANE

-

15 Shipment

15 ShipmentProducts are selected based on the shipping order and shipped after loading

※ Appearance inspection at shipment

-

Confirmation and measurement of raw materials before input

Confirmation and measurement of raw materials before inputMaterial number, thickness, width

-

Product inspection

Product inspectionProduct width, product thickness, diagonal, surface, shape

-

Product inspection after completion of work

Product inspection after completion of workProduct dimension and quantity, packaging condition inspection