Service

Quality Service

Service

Quality Service

We operate a standard table of customized quality management systems differentiated for each customer.

-

Individual storage of products and raw materials by customer • Separate storage of small residuals and long-term inventory

-

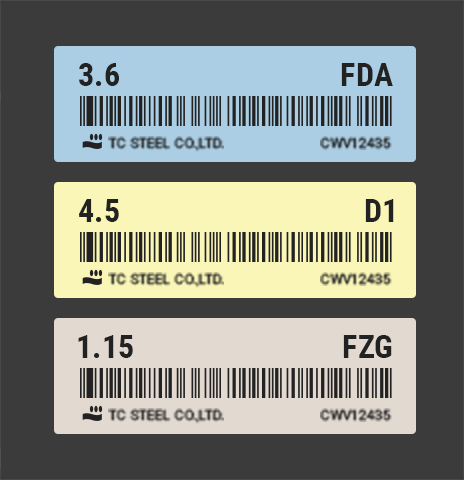

Provide packaging requested by customers (export packaging) • Exterior quality control to prevent contamination

-

Label

color

differentiation

We produce products of uniform quality using robots.

- Realize high productivity with robot work

- Easy to produce small quantity and multi-kind products

- Produce excellent products of uniform quality with powerful automatic hydraulic equipment

- Prevent quality defects with computer control system

Designate the person who acquires the inspector qualification for each line and conduct pre-inspection activities.

- Designation of inspectors who have acquired the inspector qualification

- Education on the analysis of the cause of quality defects by type and countermeasures

- External quality education supervised by the Korean Standards Association and dissemination education

- Computerized history management by preparing product inspection reports by company and material

for each line

Establish a systematic process for dealing with defects in quality.

-

01

Line stop

in case of defect -

02

Identify the cause of the defect

-

03

Notify production management

-

04

Notify the sales representative

-

05

Determine whether to proceed with the work after informing the customer

-

06

Completion of action

-

Defect has occurredfaulty

Defect has occurredfaulty -

01. Operator

-

Check defect details

Determine the defect in raw material or self-defect

-

Investigate and notify defect details

-

Prepare a nonconformity report

-

-

02. Production management

-

Check defect details

-

Inform sales representatives and customers

-

Notify the operator after deciding whether to proceed with the work

-

-

03. Follow-up management

-

Defects in raw materials

Request for investigation and CLAIM processing to POSCO

-

Process and quality defects

Consult with customer companies related to compensation and establish countermeasures to prevent recurrence

-

Defect occurrence details by company:

History management (computerized)

-